Filter Aids

The VACUCAM® Slurry Process offers efficient and dust free mixing of all filter aids including Diatomaceous Earth (D.E.) silicas and other filter aids.

FILTER AIDS

FILTER AIDS

The VACUCAM® Slurry Process offers users of activated carbon powders unparalleled surface wetting with little or no “rogue dust” emissions.

Efficient, dust free dry ingredient processing.

The VACUCAM® Slurry Process offers efficient and dust free mixing of all filter aids including Diatomaceous Earth (D.E.) silicas and other filter aids.

The VACUCAM® Slurry Process offers users of activated carbon powders unparalleled surface wetting with little or no “rogue dust” emissions. Dry side options include bulk-bag handling or Air Pallet® Container unloading coupled to the VACUCAM® Ejector Mixer. These options provide the end user with the highest level of handling ease, dust control, and high efficiency dry/liquid dispersion. The capability of using deoxygenated water and “conditioning” dry powders with CO2 or nitrogen, provides this industry with another huge benefit – immediate and extremely low oxygen levels or inerting for a “classified” area.

Handling and containment of powdered and granular filter aids such as DE and powdered or granular activated carbon (PAC/GAC). Rapid and complete vacuum convey and mix (Vacucam®) of all dry materials. Dry materials fluidized in the Air Cone Hopper® has option for utilization of CO2 vs. compressed air to effectively and efficiently drive out oxygen from pre-coat/body feeds.

Convey / Disperse / Rehydrate / Liquefy

The TOTAL SOLUTION for use of Filter Aids is provided in standardized modular skids to address mix processes and with total design dry handling systems to address dry bulk ingredients, bulk bags, paper bags or minor ingredients.

- Convey – powders from conditioned source

- Disperse – pigments, fillers, silica’s, filter aids, carbons, catalysts, spices

- Rehydrate – NFDM, whey, protein, lactose, lime

- Liquefy – sugar

- Dissolve – salts, phosphates, sweeteners

- Functionalize – thickeners, gums, starches, pectin, carbopol, etc.

- Emulsify – oils into powder / liquid mixes

- EJM/Wand or bag/box/FIBC options for “single pass” filter aid dispersions.

- In-Line carbon slurries fed from bag dump or bulk bag stations.

- MOT (mixer on tank) for master slurries of DE and/or PAC or GAC

VACUCAM® Technology

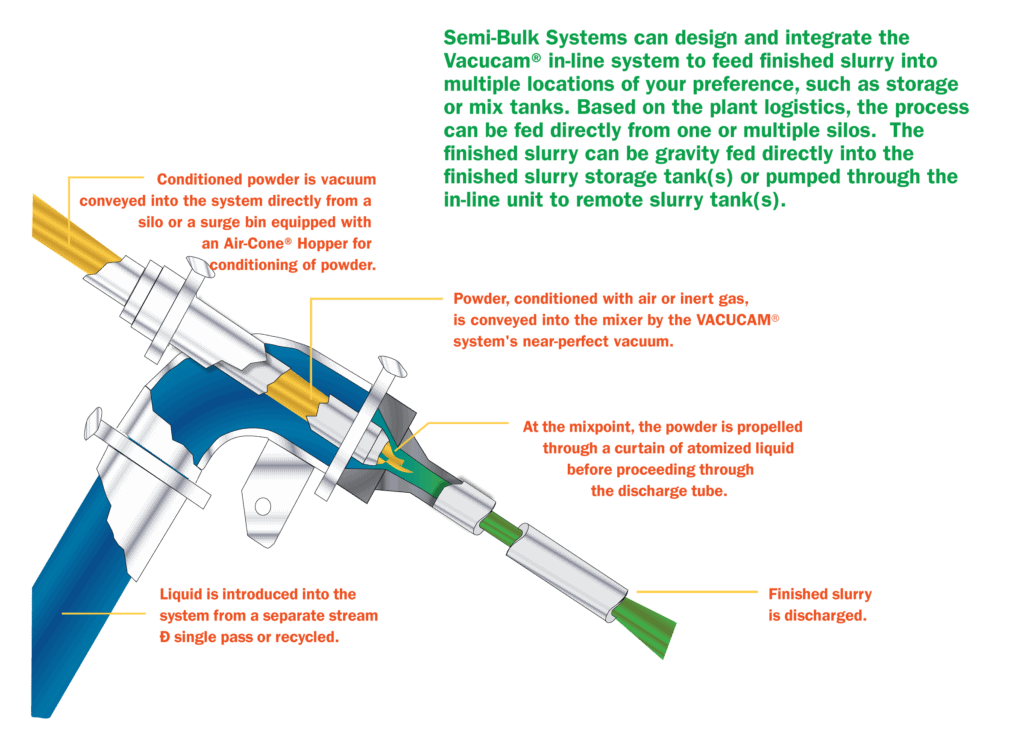

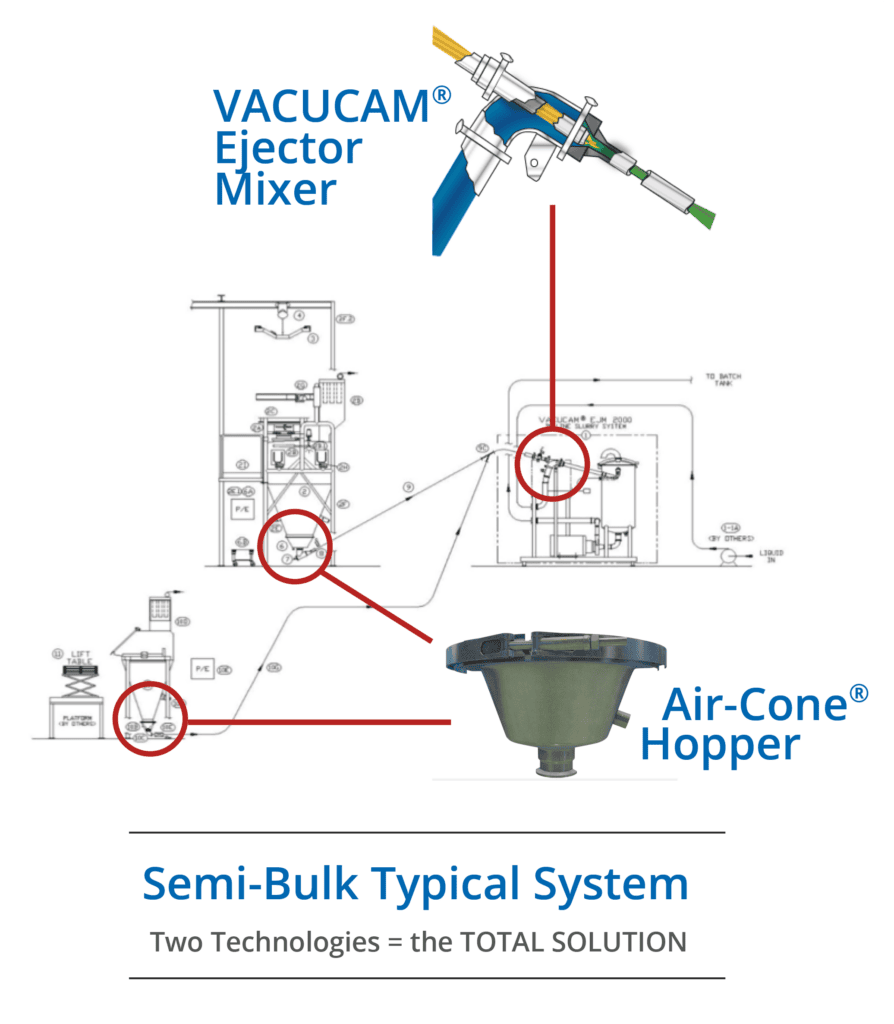

Semi-Bulk Systems can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations of your preference, such as storage or mix tanks.

Air-Cone® Hopper

The Air-Cone® Hopper’s ability to condition difficult powders makes it ideal for applications where dependable flow and total discharge are critical.

VACUCAM® Ejector Mixer

Semi-Bulk Systems VACUCAM® Ejector Mixer Dynamic Batching Station provides the most efficient dispersion, mixing and hydration of ALL dry ingredients used in today’s broad range of product types and ALL Beverage Processes.

The Vacucam® Ejector Mixer is the most effective system available for conveying, wetting, and dispersing powders into liquids.

Here is how it works.

Conditioned powder is conveyed into the mixer by a near-perfect vacuum, which is created when pressurized fluid is discharged as a high-velocity, hollow jet into which the powder is drawn.

The high speed dispersion mixer.

The Vacucam® system achieves high-speed, instantaneous and complete wetting by bringing together conditioned powder and highly atomized liquid from two separate streams, incorporating particles of liquid with particles of powder. The reactive surface areas of both the powder and the liquid are maximized before intimate contact is actually made. The result is consistently uniform, superior wetting without the agglomeration or “clumping” usually associated with conventional mixing methods.

Semi-Bulk Systems can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations of your preference, such as storage or mix tanks. Your entire process can be physically separated and centrally controlled. Semi-Bulk Systems provides options such as mounting the Ejector-Mixer on your tanks or integrating our system with your existing process.

The best fluid ejector upgrade with improved efficiency over the traditional fluid mixer.

Since the Vacucam® system achieves high-speed, instantaneous and complete mixing, it makes it perfect for fluid mixing too. You can bring together highly atomized liquids from two separate streams for batch to batch consistency and uniform mixing.

Air-Cone® Hopper

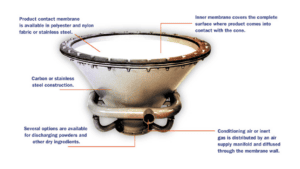

The Air-Cone® Hopper’s ability to condition difficult powders makes it ideal for applications where dependable flow and total discharge are critical. Batch-to-batch variations due to material hold-back are virtually eliminated when it is used as a weigh hopper.

Since the conditioned powder is able to flow freely, the Air-Cone® Hopper is an excellent feed source for vacuum conveyors and for the VACUCAM® Ejector Mixer above.

Here’s how the system works

An inner membrane completely covers the surface where product comes into contact with the cone. Low pressure “conditioning” air or inert gas is distributed by an air supply manifold and diffused through the membrane wall. When the dry ingredients are conditioned, they assume the properties of a liquid and can then flow smoothly and accurately into your manufacturing process. This aeration process eliminates some of the typical production problems with difficult powders such as bridging and rat holes.

Total Dry Mix Automated Process

- Single In-Line process to deliver to selected mix tanks

- Separate dry room from wet area

- Bulk bag handling of major ingredients. Paper bag handling of minor ingredients

- Multiple bulk bag hoppers for automated powder delivery of all dry ingredients

Dry Side Delivery

- Paper bags

- Bulk Truck

- Bulk Rail

- Bulk Bags

- Bulk Silo

Other Beverage Applications

CSD & Teas

Sports & Energy

Nutritional Beverages

Nutritional Beverages

The VACUCAM® is the most effective method for the complete dispersion of whey, lactose, milk proteins and other dry ingredients used in nutritional formulations.

Brewing

Filter Aids

Filter Aids

We provide the beverage industry with the single best solution for the increased sucrose demand and efficient in-plant conversion from dry sucrose-to-sucrose syrup.