Frozen Desserts

The VACUCAM® Modular Solutions offer the total solution to meet all of your mix room needs — both for today’s immediate challenges and tomorrow’s changing requirements and capacity demands.

The VACUCAM® Slurry Process is the most effective method for the complete dispersion of sugar, sweeteners, whey powders, thickeners and all other dry ingredients typically used in the manufacture of frozen desserts.

FROZEN DESSERTS

FROZEN DESSERTS

Semi-Bulk Systems has applied its Vacucam® technology and experience to provide the most efficient dispersion and mixing of Frozen Desserts ingredients used in today’s ever-expanding range of dairy product types.

Improved powder liquid mixing for batch to batch consistency.

New dairy introductions require additional process requirements:

- To handle changing ingredients that cannot be mixed efficiently with traditional mix stations or mixing technology.

- To handle bulk bag addition of ingredients as well as small packages for dry and liquid minors.

- To handle the changing needs for sweeteners and addition of totally new ingredients.

Modular Design

Modular Design

Expand your process capabilities for a TOTAL mix process.

- Meet growing and changing demands w/modular additions to existing system.

- Build TOTAL sustainable process for ALL mix requirements.

- Meet 3A/USDA specifications

- Accommodate dry feed from paper bag, drums, bulk bag or bulk.

- Achieves CIP compatibility of all components on both the dry and the wet sides of the process.

Features

- Cold dispersion capability

- Complete dynamic dispersion

- Easily mixes multiple ingredients (i.e. alternative sweeteners, and thickeners)

- No damage to fat globules in milk or cream

- Isolates dry ingredients representing allergic or other cross-contamination issues.

- Maximizes powder incorporation rates

- Full CIP capability

- Multi-functional design allows for maximum utilization.

- Sugar-on-demand – eliminates need for sucrose syrup storage. Delivers batch quantity directly into blend tank.

- Sugar – high capacity, using Semi-Bulk Systems unique powder handling / sugar liquefication processes.

- Cocoa – Integrates into UHT process with complete dispersion and controlled amount of shear on cocoa.

- Functionalize gums & stabilizers without sheer

- Meets 3A/USDA standards

- Accommodates smaller footprint – simplified unit operations

- Clean, dust-free operation – no dust collection on batch tank

- Total Automation – Integrates Batch Menu Controls.

- Improves Operator Safety & GMP

- Eliminates high frequency injuries with ergonomic process design

- Floor level operation

- Eliminates operator platforms

- Reduces manual handling by moving from small bag to bulk bag capability

Benefits

CAPACITY

- High capacity rates – can feed several bottling lines with minimum batch cycle times

- Minimum batch times

- Increase product yields

QUALITY

- Batch to batch consistency

- Improved overall mix quality. Maximized efficiency of the UHT process.

- No fisheyes/agglomerates

OPERABILITY

- Allows for parallel processing – eliminates sequential batching for functional ingredients, sweeteners, cocoa, and sugar.

- Low / No maintenance – Pump is only moving part.

- Low energy consumption

- Low labor requirements

Total Dairy Mixing Solution

The TOTAL SOLUTION for Cheese Mix making is provided in standardized modular skids to address mix processes and with total design dry handling systems to address dry bulk ingredients, bulk bags, paper bags or minor ingredients.

TYPICAL INGREDIENTS

VACUCAM® Technology

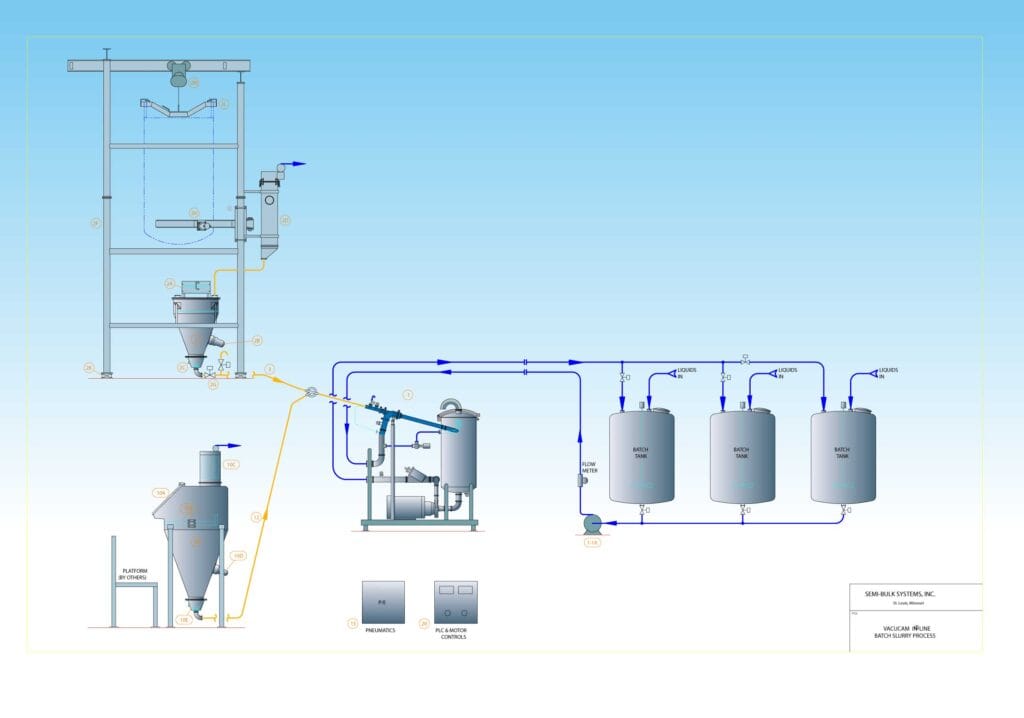

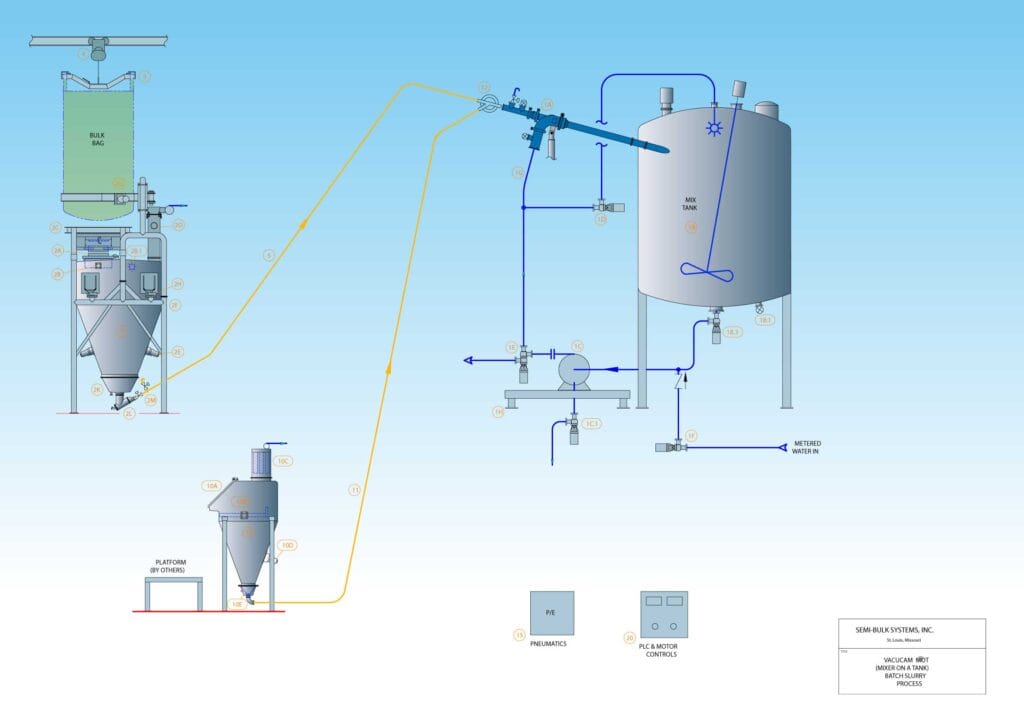

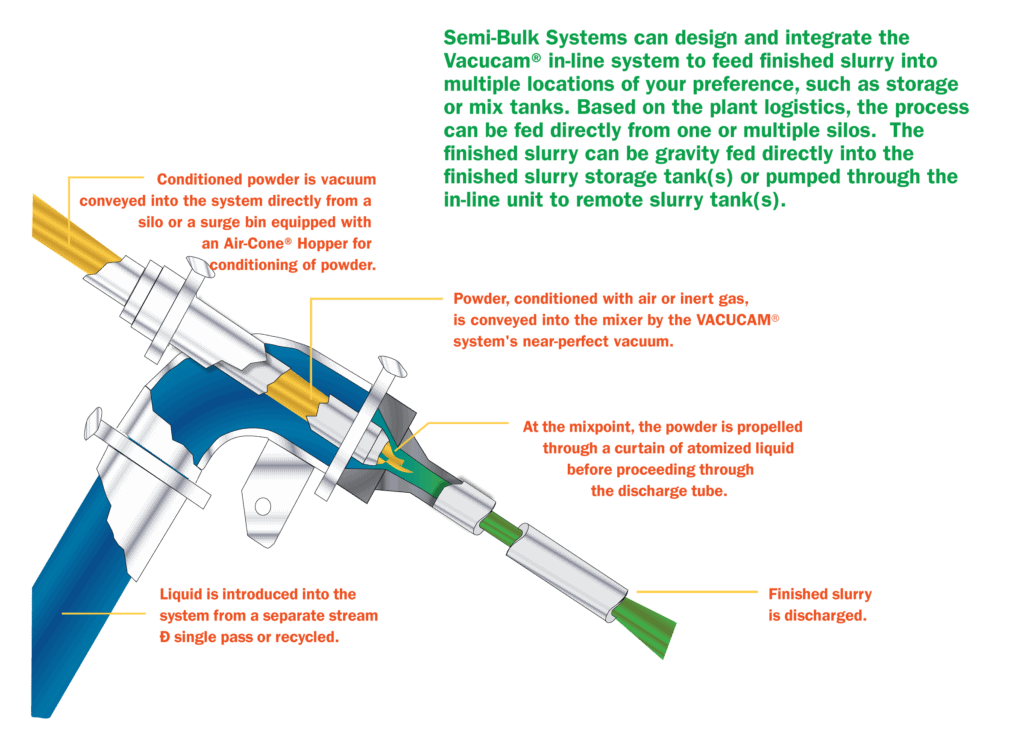

Semi-Bulk Systems can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations of your preference, such as storage or mix tanks.

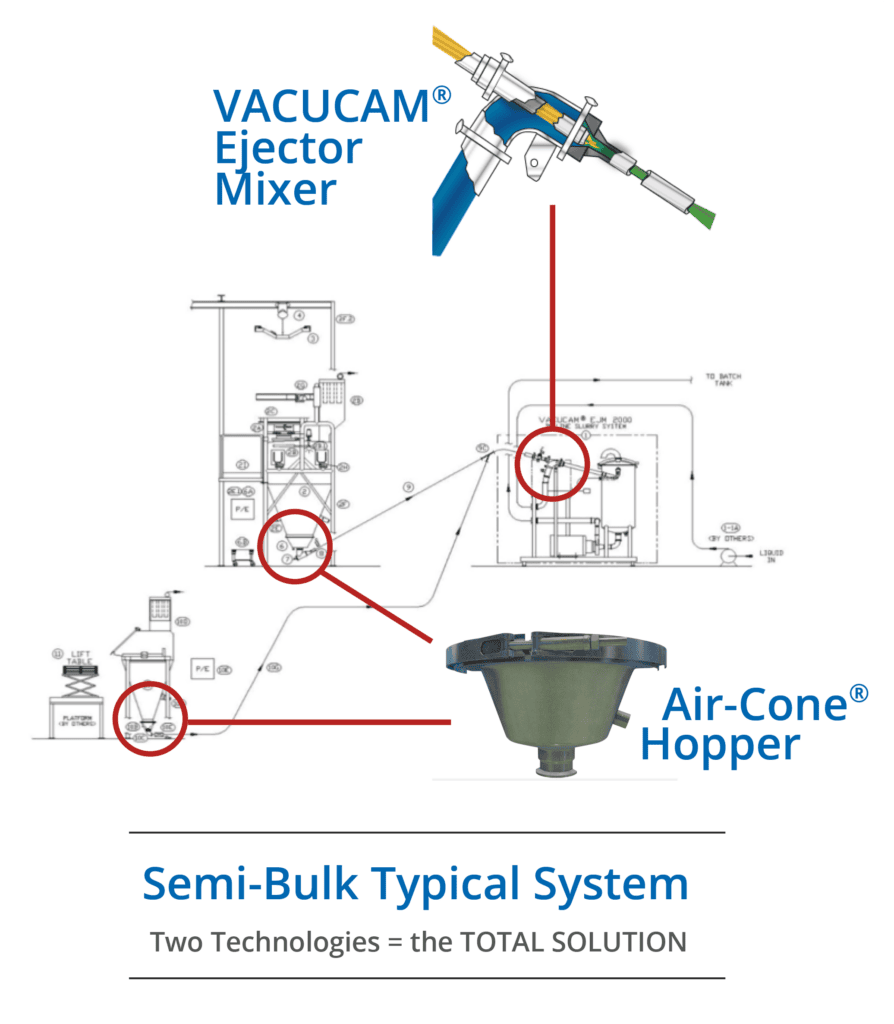

Air-Cone® Hopper

The Air-Cone® Hopper’s ability to condition difficult powders makes it ideal for applications where dependable flow and total discharge are critical.

VACUCAM® Ejector Mixer

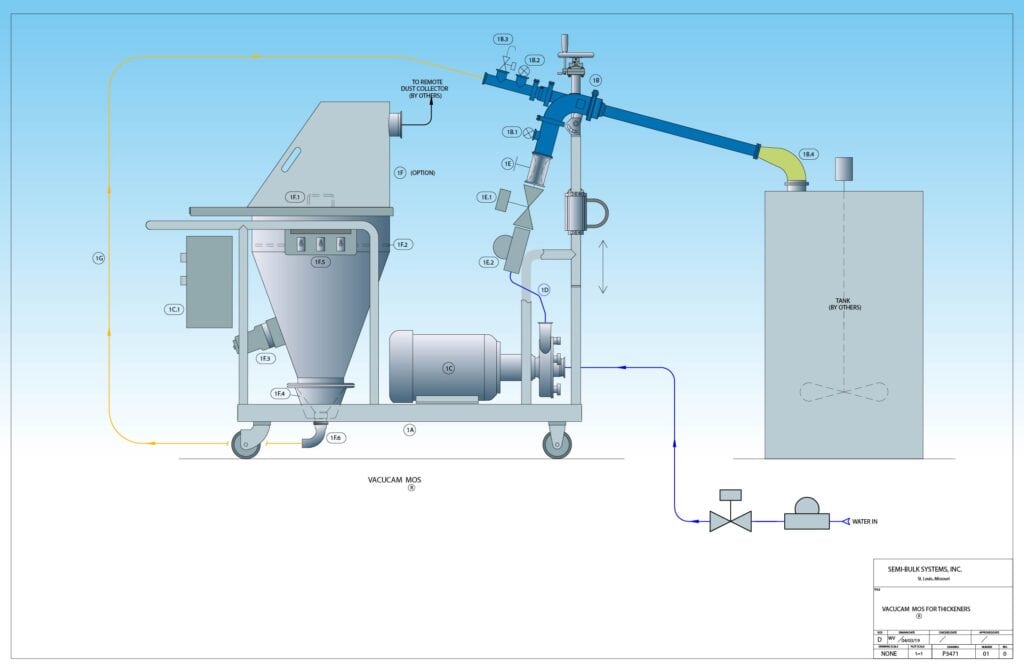

Semi-Bulk Systems VACUCAM® Ejector Mixer Dynamic Batching Station provides the most efficient dispersion, mixing and hydration of ALL dry ingredients used in today’s broad range of product types and ALL Beverage Processes.

The Vacucam® Ejector Mixer is the most effective system available for conveying, wetting, and dispersing powders into liquids.

Here is how it works.

Conditioned powder is conveyed into the mixer by a near-perfect vacuum, which is created when pressurized fluid is discharged as a high-velocity, hollow jet into which the powder is drawn.

The high speed dispersion mixer.

The Vacucam® system achieves high-speed, instantaneous and complete wetting by bringing together conditioned powder and highly atomized liquid from two separate streams, incorporating particles of liquid with particles of powder. The reactive surface areas of both the powder and the liquid are maximized before intimate contact is actually made. The result is consistently uniform, superior wetting without the agglomeration or “clumping” usually associated with conventional mixing methods.

Semi-Bulk Systems can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations of your preference, such as storage or mix tanks. Your entire process can be physically separated and centrally controlled. Semi-Bulk Systems provides options such as mounting the Ejector-Mixer on your tanks or integrating our system with your existing process.

The best fluid ejector upgrade with improved efficiency over the traditional fluid mixer.

Since the Vacucam® system achieves high-speed, instantaneous and complete mixing, it makes it perfect for fluid mixing too. You can bring together highly atomized liquids from two separate streams for batch to batch consistency and uniform mixing.

Air-Cone® Hopper

The Air-Cone® Hopper’s ability to condition difficult powders makes it ideal for applications where dependable flow and total discharge are critical. Batch-to-batch variations due to material hold-back are virtually eliminated when it is used as a weigh hopper.

Since the conditioned powder is able to flow freely, the Air-Cone® Hopper is an excellent feed source for vacuum conveyors and for the VACUCAM® Ejector Mixer above.

Here’s how the system works

An inner membrane completely covers the surface where product comes into contact with the cone. Low pressure “conditioning” air or inert gas is distributed by an air supply manifold and diffused through the membrane wall. When the dry ingredients are conditioned, they assume the properties of a liquid and can then flow smoothly and accurately into your manufacturing process. This aeration process eliminates some of the typical production problems with difficult powders such as bridging and rat holes.

Total Dry Mix Automated Process

- Single In-Line process to deliver to selected mix tanks

- Separate dry room from wet area

- Bulk bag handling of major ingredients, paper bag handling of minor ingredients

- Multiple bulk bag hoppers for automated powder delivery of all dry ingredients

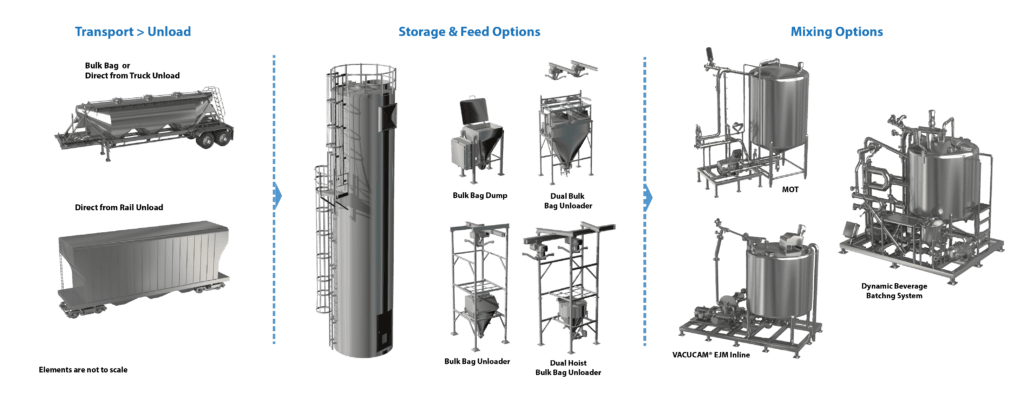

Dry Side Delivery

- Paper Bags

- Bulk Bags

- Bulk Truck

- Bulk Rail

- Bulk Silo

FAQs

Semi-Bulk solutions create batch-to-batch consistency for bulk ice cream mix.

The VACUCAM® Slurry Processes specifically address both dry ingredient handling and dry/liquid dispersion and functionalization benefits for a myriad of ingredients used in the production of frozen desserts. Cocoa powders represent problems related to dust control as well as uniform wetting and dispersions. Our processes eliminate both concerns. Gums/stabilizers are dispersed completely without agglomerates and are not exposed to excessive SHEAR. This combination reduces usage dramatically. We have designed systems that effectively produce a gum slurry followed immediately by the dispersion of cocoa powder and other ingredients into the fully hydrated gum! One of the most critical benefits to this industry is BATCH TO BATCH CONSISTENCY!

Processes for frozen dessert mix making can be designed around the VACUCAM® EJM 2000 skidded unit as the heart of the liquid side process. For processes incorporating bulk bags or paper bags of cocoa powder, a delumper or sifter may be incorporated on the dry side to reduce the product lumps before delivery into the surge hoppers.

The dry side of the process will be configured based on the volume of individual ingredients, the number of individual ingredients serving the process, and the type of package used for shipping the individual dry ingredients. Dry side system components can be a single Bag Dump Hopper for minor ingredients, a single PH Bulk Bag Surge Hopper for one bulk bag ingredient, multiple Bulk Bag surge hoppers with loss-in-weight delivery or in combination. Process controls assure accurate sequencing, delivery line sweep and limited manual intervention.

Other Dairy Applications

Cheese

Cheese

Semi-Bulk Systems has applied its Vacucam® technology and experience to provide the most efficient dispersion and mixing of Cheese ingredients used in today’s ever-expanding range of dairy product types.

Cultured Products

Cultured Products

Semi-Bulk Systems has applied its Vacucam® technology and experience to provide the most efficient dispersion and mixing of Cultured Products ingredients used in today’s ever-expanding range of dairy product types.

Frozen Desserts

Frozen Desserts

Semi-Bulk Systems has applied its Vacucam® technology and experience to provide the most efficient dispersion and mixing of Frozen Desserts ingredients used in today’s ever-expanding range of dairy product types.