Milk Powder Reconstitution

The reconstitution of Milk Powders, including NFDM, whole milk, caseins, whey protein, lactose, or other milk powder products,

can be rapidly accomplished using the VACUCAM® EJM 2000 skidded unit.

MILK POWDER RECONSTITUTION

Milk Powder Reconstitution

Vacucam® Processes are designed and built to USDA/3A specifications and include CIP compatibility of all components on both the dry and the wet sides of the process. Semi-Bulk Systems, Inc. belongs to several Dairy Industry and industry related organizations.

Milk Powder Reconstitution

The VACUCAM® unit provides 100% rapid rehydration. Depending on the unit size selected, powder rates of 300 to 550#/minute are typical with larger units capable of conveying and processing in excess of 1000#/minute. The unit will typically process 30%+ NFDM solids on a single pass with much higher solids achieved on batch recycle. A major challenge in dairy operations when adding dry powders to fluid milk to increase solids levels is in controlling finished product temperature. The Vacucam® process will fully hydrate milk powders into cold milk or water and the resultant product is able to be used immediately. The combined savings in time and energy is phenominal!

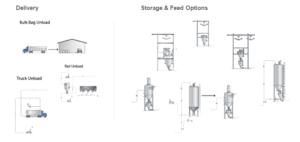

The design of the dry side feed system becomes extremely important to maintain the delivery rate to the VACUCAM® Ejector Mixer System. Bulk bags are discharged dust free into PH Bulk Bag Surge Hoppers (90, 140 or 165 cu.ft. capacities). The rate of unloading the bulk bags become the critical factor for meeting the design capacity for the process. The dry side can be designed with a single bulk bag unload hopper, dual bulk bag hoppers alternating delivery to the single VACUCAM® EJM 2000 skidded unit, or a single hopper (PH210 Bulk Bag Surge Hopper) with dual bulk bag unloading capability. The Sanitary CIP Design Hoppers are equipped with vibrating screens at the inlet, bulk bag support frames with Hugger® bulk bag massager, Load Cells, Air-Cone Hopper discharger, and other options for total automation and hands free operation.

Benefits

- High Capacity Processes—10-15tph dry powder

- Single pass-30% solids—50%+ w/ recycle

- Make fluid milk directly into silo or add solids to fluid milk

- Total hydration / no solids fall-out in silo

Convey / Disperse / Rehydrate / Liquefy

The TOTAL SOLUTION for Milk Powder Reconstitution is provided in standardized modular skids to address mix processes and with total design dry handling systems to address dry bulk ingredients, bulk bags, paper bags or minor ingredients.

- Convey – powders from conditioned source

- Disperse – pigments, fillers, silica’s, filter aids, carbons, catalysts, spices

- Rehydrate – NFDM, whey, protein, lactose, lime

- Liquefy – sugar

- Dissolve – salts, phosphates, sweeteners

- Functionalize – thickeners, gums, starches, pectin, carbopol, etc.

- Emulsify – oils into powder / liquid mixes

VACUCAM® Technology

VACUCAM® Technology

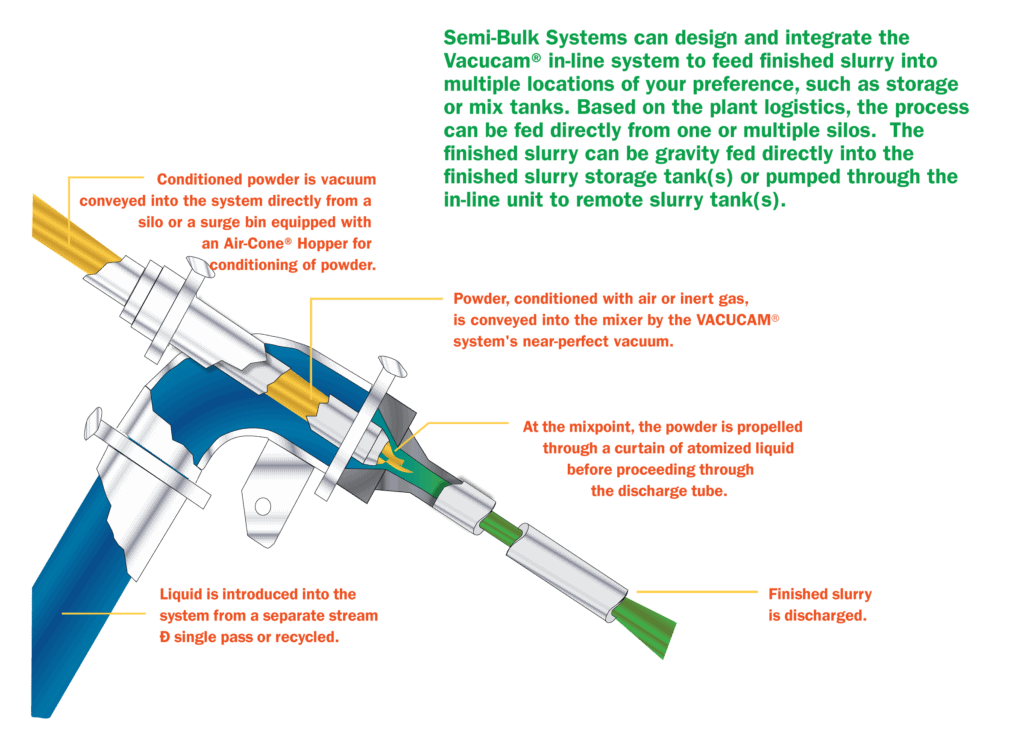

Semi-Bulk Systems can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations of your preference, such as storage or mix tanks.

Air-Cone® Hopper

Air-Cone® Hopper

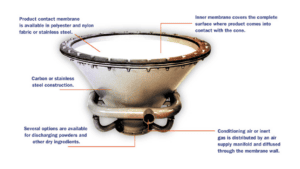

The Air-Cone® Hopper’s ability to condition difficult powders makes it ideal for applications where dependable flow and total discharge are critical.

VACUCAM® Ejector Mixer

The Vacucam® Ejector Mixer is the most effective system available for conveying, wetting, and dispersing powders into liquids. Here is how it works.

Conditioned powder is conveyed into the mixer by a near-perfect vacuum, which is created when pressurized fluid is discharged as a high-velocity, hollow jet into which the powder is drawn.

The high speed dispersion mixer.

The Vacucam® system achieves high-speed, instantaneous and complete wetting by bringing together conditioned powder and highly atomized liquid from two separate streams, incorporating particles of liquid with particles of powder. The reactive surface areas of both the powder and the liquid are maximized before intimate contact is actually made. The result is consistently uniform, superior wetting without the agglomeration or “clumping” usually associated with conventional mixing methods.

Semi-Bulk Systems can design and integrate the Vacucam® in-line system to feed finished slurry into multiple locations of your preference, such as storage or mix tanks. Your entire process can be physically separated and centrally controlled. Semi-Bulk Systems provides options such as mounting the Ejector-Mixer on your tanks or integrating our system with your existing process.

The best fluid ejector upgrade with improved efficiency over the traditional fluid mixer.

Since the Vacucam® system achieves high-speed, instantaneous and complete mixing, it makes it perfect for fluid mixing too. You can bring together highly atomized liquids from two separate streams for batch to batch consistency and uniform mixing.

Air-Cone® Hopper

The Air-Cone® Hopper’s ability to condition difficult powders makes it ideal for applications where dependable flow and total discharge are critical. Batch-to-batch variations due to material hold-back are virtually eliminated when it is used as a weigh hopper.

Since the conditioned powder is able to flow freely, the Air-Cone® Hopper is an excellent feed source for vacuum conveyors and for the VACUCAM® Ejector Mixer above.

Here’s how the system works

An inner membrane completely covers the surface where product comes into contact with the cone. Low pressure “conditioning” air or inert gas is distributed by an air supply manifold and diffused through the membrane wall. When the dry ingredients are conditioned, they assume the properties of a liquid and can then flow smoothly and accurately into your manufacturing process. This aeration process eliminates some of the typical production problems with difficult powders such as bridging and rat holes.

Total Dry Mix Automated Process

- Single In-Line process to deliver to selected mix tanks

- Separate dry room from wet area

- Bulk bag handling of major ingredients. Paper bag handling of minor ingredients

- Multiple bulk bag hoppers for automated powder delivery of all dry ingredients

Dry Side Delivery

- Paper bags

- Bulk Truck

- Bulk Rail

- Bulk Bags

- Bulk Silo

Other Dairy Applications

Cheese

Cheese

Processes cheese mixes can be addressed with Semi-Bulk System’s VACUCAM® EJM 2000 skidded unit as the heart of the liquid side process, accommodating processes for single pass or batch recycle processes.

Ice Cream & Yogurt

Nutritional Beverages

Nutritional Beverages

The VACUCAM® is the most effective method for the complete dispersion of whey, lactose, milk proteins and other dry ingredients used in nutritional formulations.

Sugar Liquefication

Sugar Liquefication

We provide the beverage industry with the single best solution for the increased sucrose demand and efficient in-plant conversion from dry sucrose-to-sucrose syrup.